Testimonials

CLC

Explore Products by Category

Frequently Asked Questions

buyer's guide

What is the typical delivery time?

The standard equipment model typically arrives in 6 to 8 weeks.

For custom engineering models, delivery times are mutually confirmed in the quotation process, usually within 12 weeks.

What forms of payment does CLC accept?

CLC accepts US dollars; all types of foreign currencies must be paid at the current exchange rate.

Deposits can be paid online by credit card, while the balance payment can be made via cheque or bank transfer.

Where can I obtain a quote to plan my budget?

To receive an instant quote, click the email button on the product page.

If you require custom engineering models or wish to build your own, please contact us. Our contact information is listed at the bottom of every page.

Services

Is it possible to receive a free demo before making a purchase?

Yes.

We propose the equipment based on the customer’s application.

Assisting the customer in achieving the desired processing capability is the crucial first step to ensuring satisfaction.

What is the warranty policy for equipment and parts?

The standard warranty for equipment is 2 years for fiber and CO2 lasers, and 1 year for other lasers. It includes parts and labor free of charge, with travel expenses reimbursed based on actual spending.

Services for parts, accessories, and ancillary devices are covered for 90 days.

These warranties apply as long as the equipment or parts have not been modified without authorization.

For detailed clauses, click here.

What service plans are currently available?

After sales, we provide two types of field service plans:

Preventive Maintenance plans: Annual and Biannual

Priority Assurance Plans:

- Silver plan (laser source only)

- Gold plan (laser source, labor, & travel)

- Platinum plan (laser source, workstation, labor, & travel)

Tech evaluator Guide

What is the crucial factor in choosing a laser manufacturer?

Firstly, when evaluating laser manufacturers, focus on their controller and software capabilities.

A qualified manufacturer will have their own controller and an in-house team of electrical and software engineers.

Conversely, an unqualified manufacturer may rely on third-party controllers and software, which can lead to service and troubleshooting issues.

What are the key modules of laser equipment?

The key modules & sub-systems include:

- The laser source and beam delivery controller

- Work piece positioning sub-systems

- The three options are fixtures, machine vision components, and robot components.

- The fume extractor, along with other supporting ancillary devices.

How can I ensure that I purchase the appropriate laser for my application?

To ensure you acquire the correct laser with the desired processing capabilities, it’s best to request a FREE workpiece sample test first.

This test will establish the equipment acceptance criteria based on the results.

If your application doesn’t require high precision and you have laser processing experience, you can purchase directly based on the demo. In this case, CLC’s outgoing QC standards will serve as the acceptance criteria.

Typically, the laser reaction spot is smaller than 30 microns, or the repetition is less than 10 microns.

custom Engineering

What sets CLC's engineering service apart from others?

With a comprehensive range of wavelength laser application labs and over 50 years of experience, we can suggest the ideal laser for your project.

Our engineering team consists of optical, mechanical, electrical, and software engineers, enabling us to develop our own laser system controller and software. This allows us to undertake laser custom jobs based on your unique requirements.

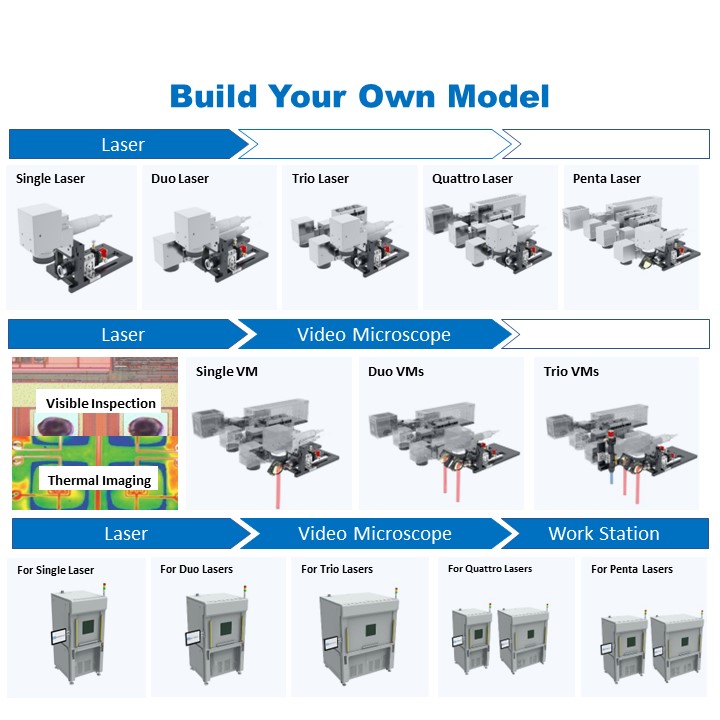

What options are currently available?

Explore “Build My Own” to see all available options, which generally include:

- XY table, Rotary, & Dial motion work station

- Fixtures on conveyor

- Fixture plate on auto feeder

- Linear robot

- 6 joint robot

- Machine vision, including video microscope

- Special designs for dusty, or oily, work environments, extreme temperature, waterproof, mark recognition proof etc.

What are the quality and safety standards?

Our standard models adhere to FDA CDRH and OSHA safety standards by default.

Custom engineering jobs can be tailored to meet UL, CE, or CSA quality assurance criteria upon request.

Software

Is it possible to synchronize laser job data with a cloud-based ERP system?

Yes, we can customize the software to your specifications:

- Connect to an on-premise or cloud based database, configured as either the client or server according to your preference.

- Operates seamlessly with any relational database such as SQL servers, Oracle, or Microsoft Access.

- Communicate through Web Service calls.

- Supports JSON or XML based messages.

Is it possible to generate complex serial numbers or characters?

Absolutely! Our in-house developed software, LMS, has been evolving for over 25 years.

Key features of LMS include:

- The ability to create and edit vector or raster graphic marks.

- Automatically generate serial numbers, text. mixtures, or arrays

- Advanced barcode and 2D code generation with 27 types.

Is it possible to obtain custom software for specific hardware?

Yes. Upon request, we provide custom software development services tailored to specific hardware, including electrical safety components, designated brand robots, and motion control stages.