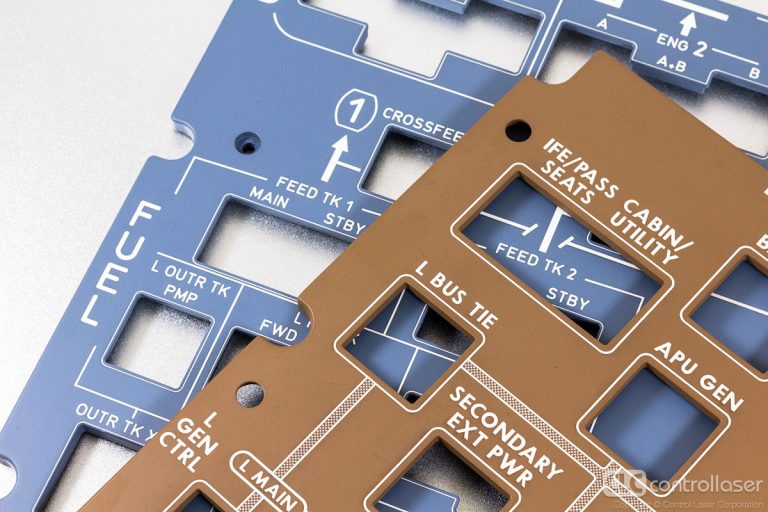

Laser System Special Design For Aerospace

for job shop of avionics panel, aircrafts and rocket parts, aerospace subassembly

AeroMark® is the aerospace laser micromachining processing solution, perfect quality and compliant with MIL-STD regulations.

It is a complete MIL-STD UID compliance application solution for aircraft backlit panel laser marking and other aerospace parts manufacturers.

CLC’s laser backlit ablating technology rooted from a laser marking system customized for Lockheed Martin in 1972.

Trademark registered in 2014.

Major users are the military, civil aircraft and rocket manufacturers, defense engineering houses, and other job shops for backlit avionics panels, aircraft and rocket parts, and aerospace sub-assembly manufacturers.

SpaceX, NASA jet propulsion lab, NASA Johnson Space Center, Kenndy Space Center, NavyAir, Lockheed Martin, Raytheon, Honeywell, GE Dynamics, Boeing Defense, BAE Systems, Orbit Science, Aerospace labs, Goodrich, Brazilian Aeronautical Commission, and more!

We developed No Nick laser wire stipping technology since 2009, take advantages of physicial principle of IR laser, our machine can guarantee non-damage of metal wire core and perfectly strip and slit the wire insulation. Custom automation for aerospace lab scientist available.

1970 – Developed the backlit laser ablating application for Pratt & Whitney avionics panels

1997 – Developed 12-inch large scale high precision optical and axis motion synchronization system

1998 – Integrated machine vision system for positioning and verification of markings

2004 – CLC’s application team started developing the backlit laser ablating compliance project

2013 – Established internal ITAR isolation procedures

2014 – Registered trademark and mass marketing

2015 – Launched new laser source integration for high-quality shading of the engraved cavity

2016 – Launched LMS version 3.1 with enhanced sectioning and stitching technology

2017 – Launched 6-jointed robot integration options