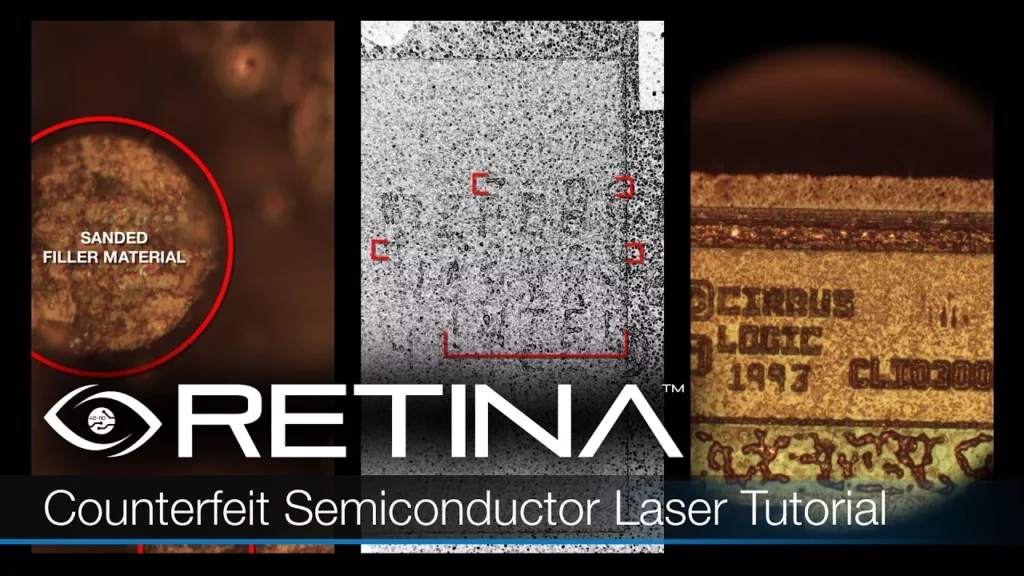

RETINA® – DIE mark counterfeit verification on silicon wafer after fully laser decapsulation

Laser de-layering process can precisely remove the RDL, via hole and other MEMS structure to expose the desired inner inspection.

RETINA® – DIE number verification on silicon wafter

RETINA® – DIE number verification on silicon wafter

Retina® Ultrafast Laser Micromachining – Glass Cutting

Retina® Ultrafast Laser Micromachining: Glass cutting with an ultrafast laser Bessel cutting head and high-precision marble stage.

RETINA® Pico Laser Application Glass, Sapphire Cutting and Engraving

Check out Control Laser clear glass laser cutting technology. No chipping on the glass. Cutting edge is clean and smooth with a great surface roughness.

RETINA™, Control Laser Corp, laser micromachining, IC Chip Counterfeit Inspection Application demo

Using patented laser technology from Control Laser Corporation, the RETINA™ Counterfeit Semiconductor Laser verifies if a semiconductor is counterfeit in three simple steps. In most cases, you can process a molded semiconductor in under 15 minutes without harmful chemicals. This method provides highly reliable results to reveal ghost marks, abrasive marks, and die marks. The RETINA™ system documents each layer of the process through its coaxial vision system. With RETINA™, you can effectively combat counterfeit semiconductors.