InstaCNC®: High-Speed, Multi-Task CNC Machining Center for Precision Machine Shops and Manufacturers of Firearms and Auto Parts

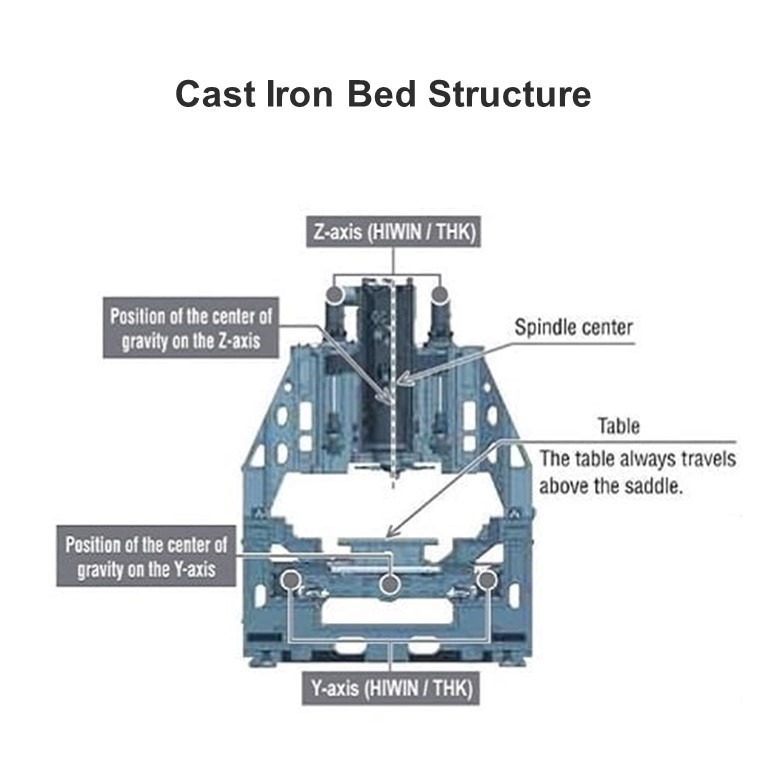

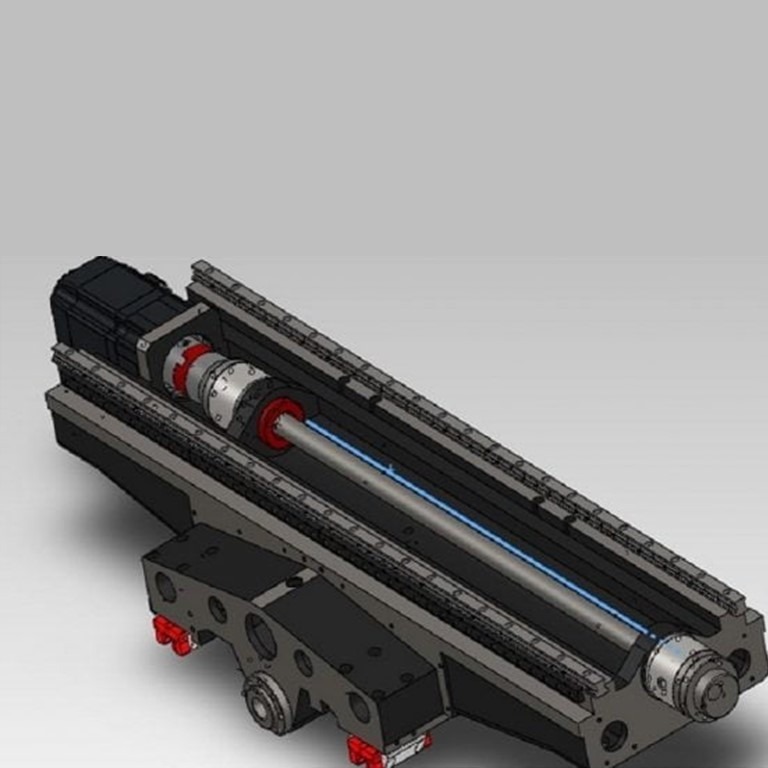

The lightweight and highly rigid column structure ensures a low starting load and quick response of the Z-axis.

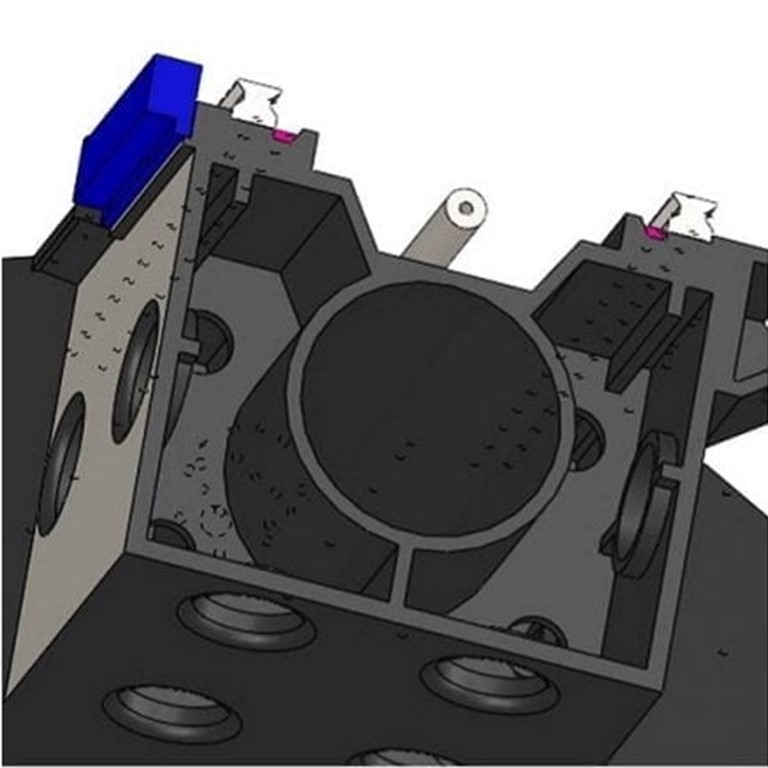

Additionally, we design the main spindle and related components with a 1.25 safety factor. Which increases to 1.6 to 2.0 during normal machining work at 8000-10000 RPM, providing exceptionally high impact resistance.

Employing a Box-in-Box design and a large-span structure, this machine attains both low weight and high rigidity, ensuring optimal performance.

Compared to competitor models, it weighs 20% less.

Moreover, the central structure boasts a large O-shape design, significantly enhancing both vertical and horizontal rigidity.

Our innovative design enhances tool holder catch capabilities.

We’ve developed, customized, and patented this mechanism to bolster spindle impact resistance, thereby extending its lifespan and preserving precision.

Speed Performance:

Unlike traditional funnel-shaped tool magazines with a maximum of 16 pockets, our innovative design features a 20-pocket high-volume tool magazine. This allows for increased processing flexibility and efficiency.

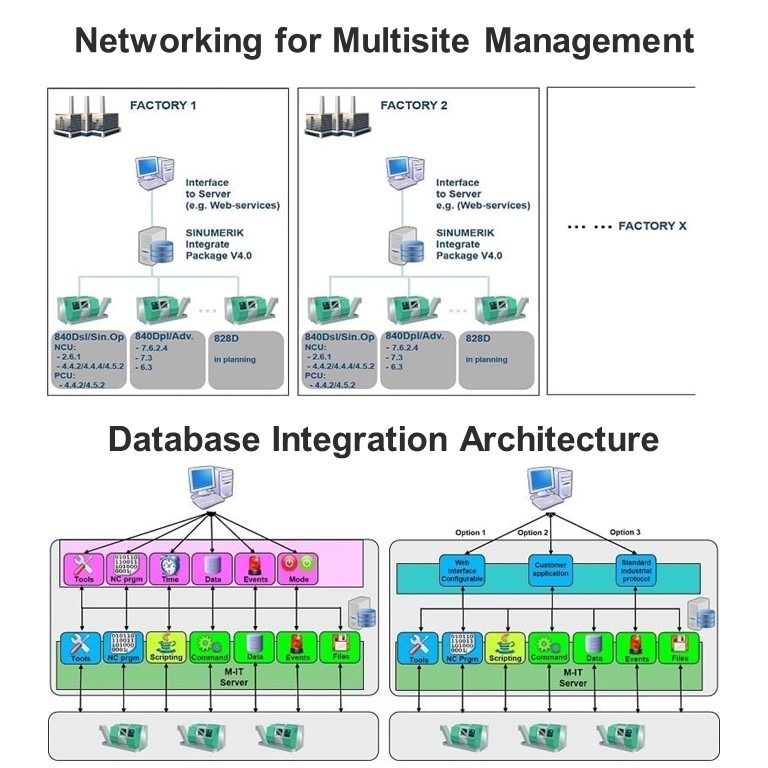

Cloud Database Integration

No need for complex intranet setups. Seamlessly transmit data via the internet and automatically share it with your smartphone and server

Smartphone Application

Leverage our smartphone app to remotely manage the machine from anywhere in the world using internet connectivity.