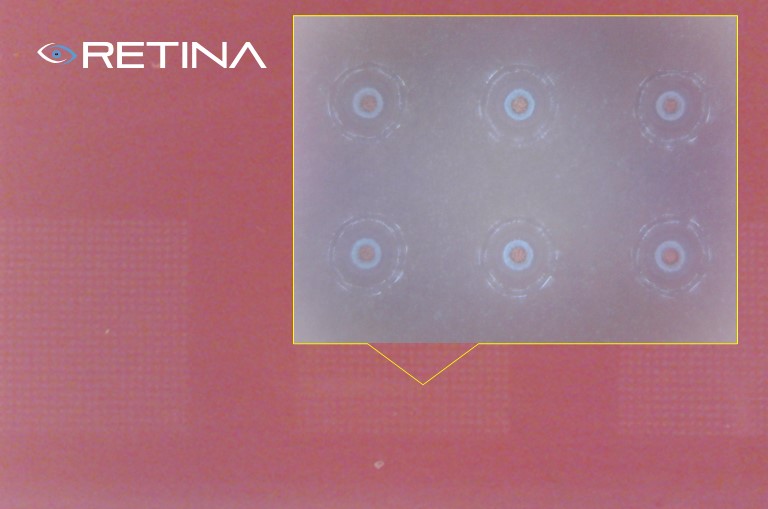

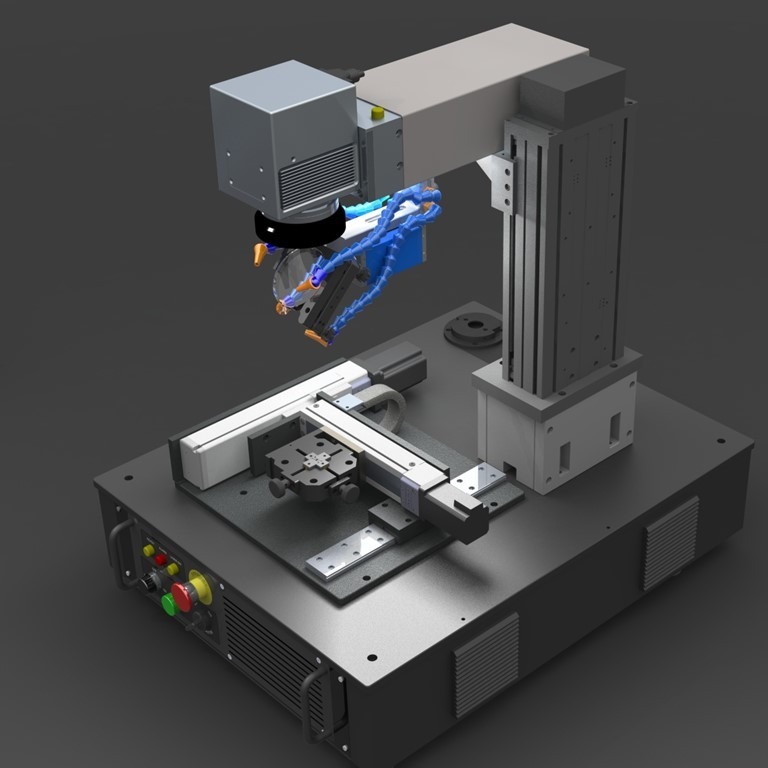

RETINA®: Offering solutions for deductive microforming and zero-taper drilling applications, employing short-wavelength and ultrafast laser sources.

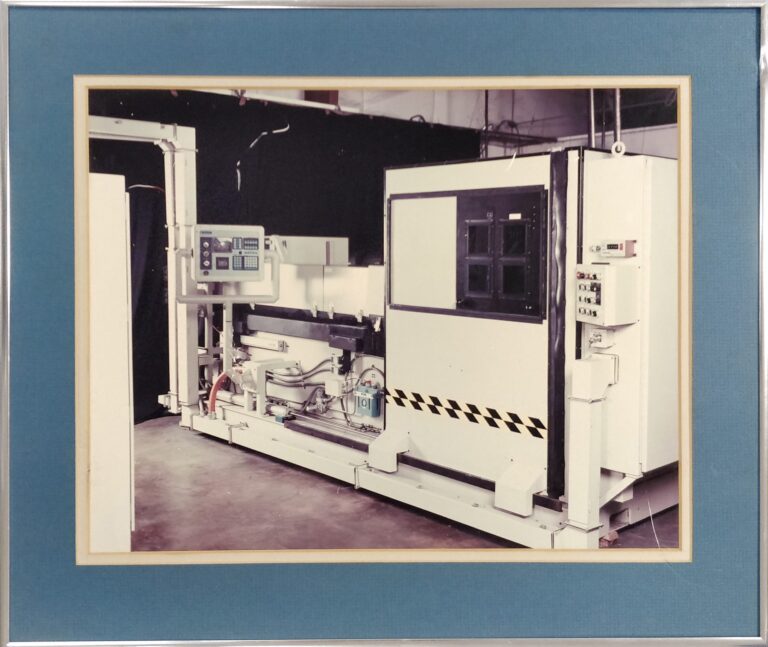

CLC’s laser micromachining technology originated from the application of laser micro-drilling on jet engine turbine blades for Pratt Whitney in 1972.

Lasers configured in RETINA

Click to toggle out the laser specifications, call us to discuss your application the custom requirements today:

Laser Type: DPSS Green Laser

Wavelength (nm): 532

Maximum Output Power (Watt): 10

Frequency Operating Range (kHz): 10-200

Cooling: Air Cooled

Warranted Working Hours: 2 Years or 10,000 hrs, whichever occurs first

Estimated Life Working Hours: 15,000 hrs.

Environment Temperature: 50~95°F (10~35 °C)

Environment Humidity (%): 0~80% Non-condensed

Default Lens (EFL, mm): f160

Laser Type: DPSS Green Laser

Wavelength (nm): 532

Maximum Output Power (Watt): 25

Frequency Operating Range (kHz): 10-200

Cooling: Water Cooled

Warranted Working Hours: 2 Years or 10,000 hrs, whichever occurs first

Estimated Life Working Hours: 15,000 hrs.

Environment Temperature: 50~95°F (10~35 °C)

Environment Humidity (%): 0~80% Non-condensed

Default Lens (EFL, mm): f160

Laser Type: Picosecond Pulsed Green Laser

Wavelength (nm): 532

Maximum Output Power (Watt): 20

Frequency Operating Range (kHz): 1-1,000 or 2,000-8,000

Cooling: Water Cooled

Warranted Working Hours: 2 Years or 17,520 (2 x 365 Days, 24 Hours/Day), whichever occurs first

Estimated Life Working Hours: 50,000

Environment Temperature: 59~86°F(15~30°C)

Environment Humidity (%): 0~80% Non-condensed

Default Lens (EFL, mm): f160

Laser Type: UV Laser

Wavelength (nm): 355 ± 5

Maximum Output Power (Watt): 10

Frequency Operating Range (kHz): 20-200

Cooling: Water Cooled

Warranted Working Hours: 2 Years or 10,000 hrs, whichever occurs first

Estimated Life Working Hours: 15,000

Environment Temperature: 50~95°F (10~35 °C)

Environment Humidity (%): 10~95% Non-condensed

Default Lens (EFL, mm): f160

Laser Type: Picosecond Pulsed UV Laser

Wavelength (nm): 355

Maximum Output Power (Watt): 10

Frequency Operating Range (kHz): 1-1,000 or 2,000-8,000

Cooling: Water Cooled

Warranted Working Hours: 2 Years or 17,520 (2 x 365 Days, 24 Hours/Day), whichever occurs first

Estimated Life Working Hours: 50,000

Environment Temperature: 59~86°F(15~30°C)

Environment Humidity (%): 0~80% Non-condensed

Default Lens (EFL, mm): f160

Laser Type: Picosecond Pulsed UV Laser

Wavelength (nm): 355

Maximum Output Power (Watt): 20

Frequency Operating Range (kHz): 0-3,000 or 2,000-8,000

Cooling: Water Cooled

Warranted Working Hours: 2 Years or 17,520 (2 x 365 Days, 24 Hours/Day), whichever occurs first

Estimated Life Working Hours: 50,000

Environment Temperature: 59~86°F(15~30°C)

Environment Humidity (%): 0~80% Non-condensed

Default Lens (EFL, mm): f160

Laser Type: Picosecond Pulsed IR Laser

Wavelength (nm): 1,064

Maximum Output Power (Watt): 50

Frequency Operating Range (kHz): 50-1,000

Cooling: Water Cooled

Warranted Working Hours: 2 Years or 17,520 (2 x 365 Days, 24 Hours/Day), whichever occurs first

Estimated Life Working Hours: 50,000

Environment Temperature: 59~86°F(15~30°C)

Environment Humidity (%): 0~80% Non-condensed

Default Lens (EFL, mm): f160

Laser Type: Picosecond Pulsed IR Laser

Wavelength (nm): 1064

Maximum Output Power (Watt): 70

Pulse Width (ps): <10

Max Pulse Energy(uj):1-10×200

Cooling: Water Cooled

Polarization: Linear

Output aperature: 2mm

Warranted Working Hours: 2 Years or 17,520 (2 x 365 Days, 24 Hours/Day), whichever occurs first

Estimated Life Working Hours: 50,000

Environment Temperature: 68~86°F(20~30°C)

Environment Humidity (%): 0~50% Non-condensed

Default Lens (EFL, mm): f160

Laser Type: Femtosecond Pulsed IR Laser

Wavelength (nm): 1,040

Maximum Output Power (Watt): 8

Frequency Operating Range (kHz): 200-1,000

Cooling: Water Cooled

Warranted Working Hours: 2 Years or 17,520 (2 x 365 Days, 24 Hours/Day), whichever occurs first

Estimated Life Working Hours: 30,000

Environment Temperature: 64~86°F(18~30°C)

Environment Humidity (%): 0~80% Non-condensed

Default Lens (EFL, mm): f160

RETINA® is primarily utilized by precise micro-machining job shops in industries such as aerospace, military, and medical devices. It is also favored in the pharmaceutical, semiconductor, automotive, and new energy sectors.

Adaptable to a Wide Range of Materials

Utilizing short-wavelength or ultrafast laser sources, it efficiently processes both organic and non-organic materials. These include metal, glass, ceramic, graphite, plastics, rubber, fiber, and composites.

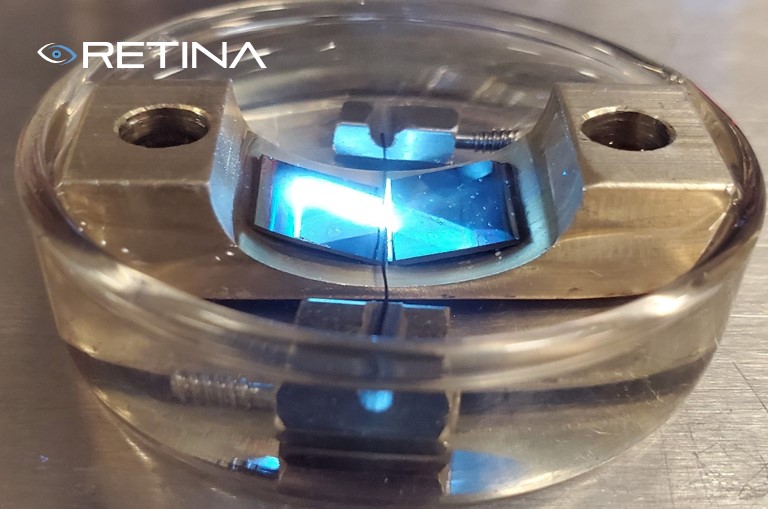

Integration of Microscope & Micro Motion Stage

The system combines a high-precision motion control stage, operating with 1~5 micron repetition, with a video microscope.

Refinement in Laser Technology

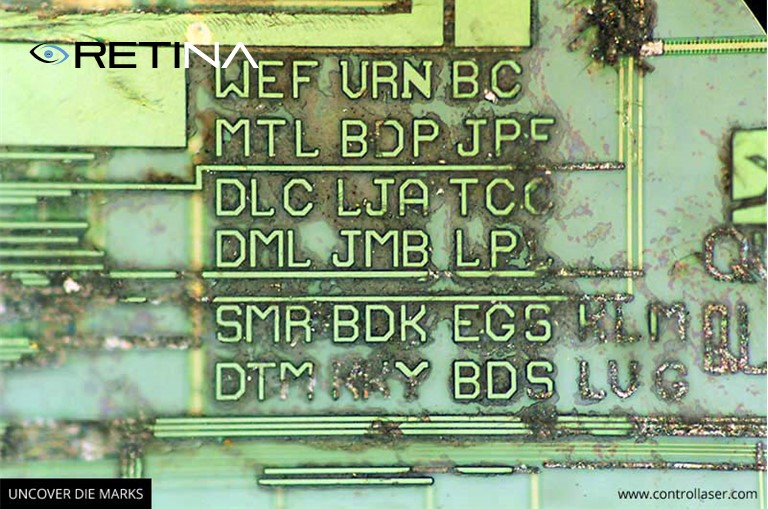

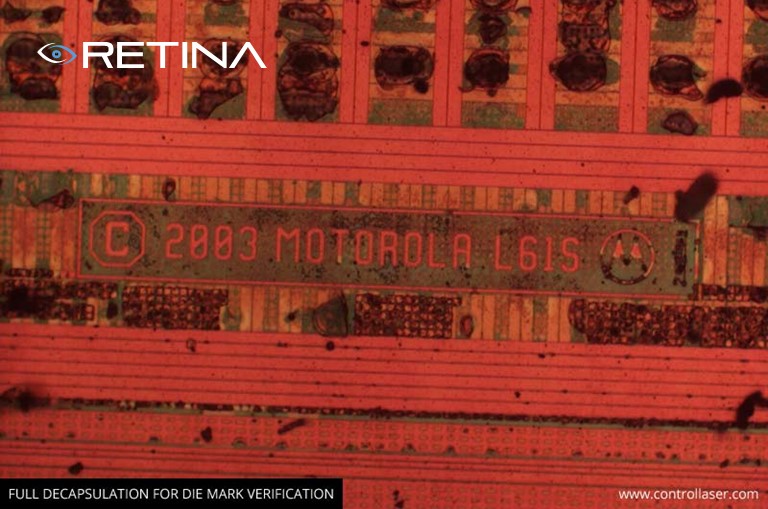

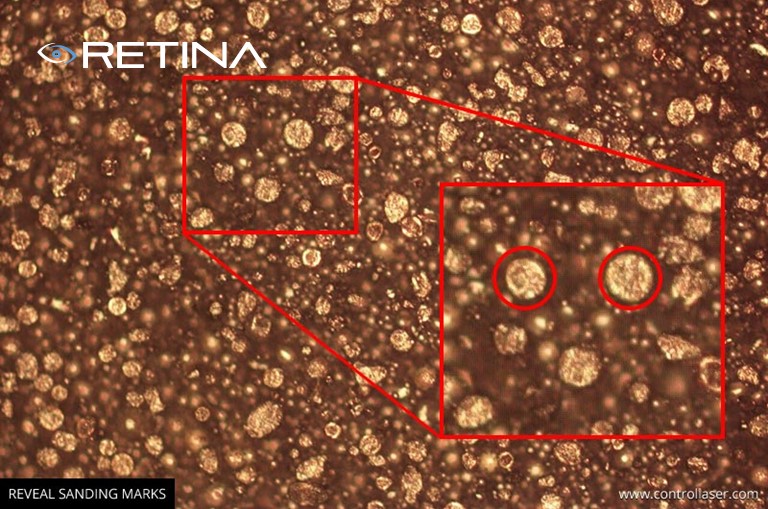

The system enables micro-forming processes inaccessible to traditional mechanical machining or chemical etching methods. It offers solutions for wafer laser marking, annealing, scribing, or dicing. Additionally, it handles tasks such as glass, sapphire, ceramic, and metal grooving or micro-drilling, blind hole drilling, micro 3D forming, and selective layer removal.

Transform Application Challenges into Added Value

By utilizing this laser micromachining technology, users can overcome various processing challenges with new and special materials. The exceptional capabilities of laser technology enable equipment owners to significantly enhance their return on investment through revenue and margin generation.